NEMESIS™ - Stealth Resin Systems

Engineered to be seen by designers—and unseen by radar

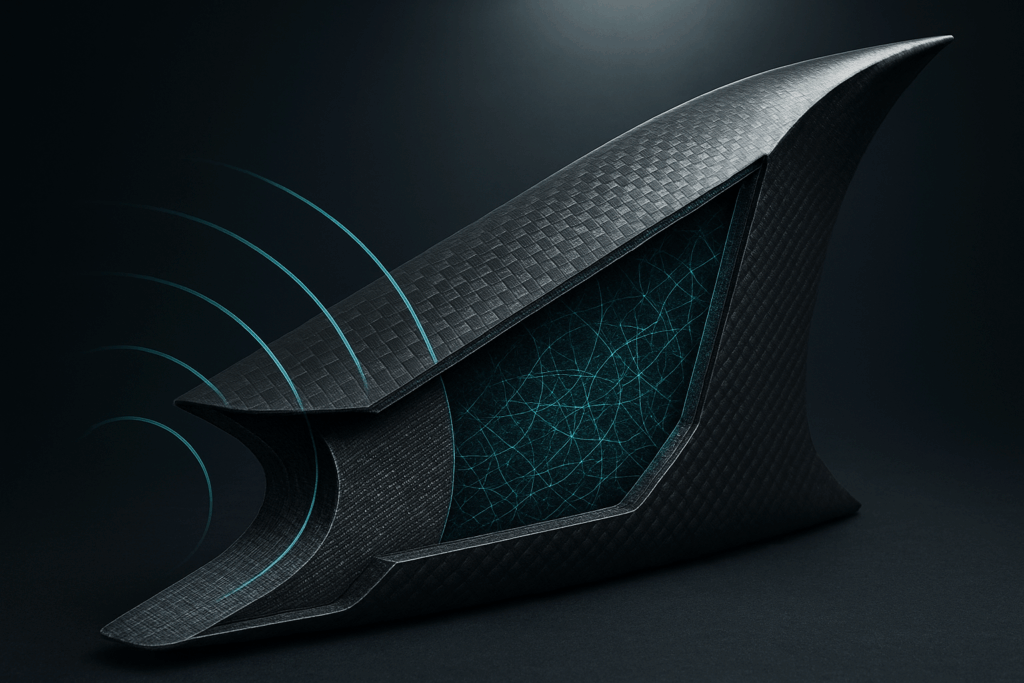

What NEMESIS™ is

A family of aerospace‑grade epoxy matrices that embeds a proprietary nano‑network directly into the resin. The result: broadband radar‑wave absorption and fully structural performance in a single laminate, no RAM paints or add‑on panels required.

Key value points

Broadband Stealth – double‑digit reduction of reflected energy from S‑band up through Ku‑band in laminates only a few millimetres thick.

Process Friendly – viscosities in the low‑thousand‑centipoise range; identical gel‑time and exotherm to mainstream aerospace epoxies.

Power‑to‑Weight Advantage – measurable gains in tensile modulus and compression strength while keeping part weight neutral.

Plug‑and‑Play with XHT – co‑infusion, co‑cure and direct bonding are all possible without primers or cycle changes.

IP‑Locked Formulation – every critical ingredient is sourced through Reinvetny’s secure supply chain and protected by patents & NDAs.

Product line‑up

| Product | Fibre Focus | Stealth Profile | Typical Cure Window |

|---|---|---|---|

| NEMESIS™ S‑Lite | Carbon fabrics & UD | Broadband –14 dB (5–18 GHz) | 100 °C × 4 h @ 2 bar |

| NEMESIS™ S‑Core | Carbon fabrics & UD | Enhanced –15 dB (1 % hybrid) | 100 °C × 4 h @ 2–4 bar |

| NEMESIS™ S‑Gradient | Carbon fabrics & UD | Ultra‑wideband –18 dB (gradient stack) | 100 °C × 4 h @ 6 bar |

| NEMESIS™ BX‑Lite | Glass biax 300–600 g m‑2 | Broadband –11 dB (5–18 GHz) | 100 °C × 4 h @ 2 bar |

| NEMESIS™ BX‑Core | Glass biax 300–600 g m‑2 | Enhanced –14 dB (1 % hybrid) | 100 °C × 4 h @ 2 bar |

| NEMESIS™ BX‑Gradient | Glass biax 300–600 g m‑2 | Ultra‑wideband –18 dB (gradient stack) | 100 °C × 4 h @ 6 bar |

| NEMESIS™ Film‑Bond | — adhesive film | Stealth bond‑line (tan δ tuned) | 120 °C × 1 h (bond‑line) |

| NEMESIS™ Prepreg‑OOA | ±45° glass / carbon | –10 dB patch/repair | 90 °C × 2 h bag cure |

NEMESIS™ S‑Lite

Stealth‑ready epoxy matrix for carbon‑fiber structures

NEMESIS™ S‑Lite — Carbon‑Fiber, Low‑Observable by Default

Lightweight, process‑friendly and fiercely stealthy: S‑Lite lets you turn any carbon‑fiber skin or control surface into a broadband absorber—without touching the lay‑up schedule you already run. A 0.5 wt % hybrid nano‑network is all it takes to cut the radar echo by double digits while boosting tensile stiffness. Cure it alongside your XHT parts, paint it in the same booth, and fly away invisible.

Variants at a glance

| Variant | What it is | Why you’d choose it |

|---|---|---|

| S‑Lite | 0.5 % filler, baseline stealth | Drop‑in for primary skins and winglets that need –14 dB across X/Ku. |

| S‑Core | 1 % filler, higher loss tangent | Pushes attenuation to –15 dB and adds ~3 % modulus—perfect for hot‑spot shielding between bulkheads. |

| S‑Gradient | 2 → 1 → 0.5 % stacked layers | Ultra‑wideband –18 dB coverage (5–18 GHz) in a single 3 mm laminate; use it where the threat spectrum is unknown. |

| Property (typical) | Value* |

|---|---|

| Hybrid nano‑filler content | 0.5 wt % |

| εʀ @ 6 GHz | 6.2 ± 0.2 |

| tan δ @ 6 GHz | 0.18 |

| RCS attenuation† | –14 dB @ 10 GHz, 25° |

| Tensile modulus (UD 600 g m⁻², 2 bar) | 3.5 GPa |

| Post‑cure Tg | 145 °C |

| Viscosity 25 °C | 1 150 cPs |

* 2.5 mm laminate, 100 °C × 4 h cure. † Arch‑type measurement on 250 × 250 mm panel

Key benefits

Drop‑in for CFRP processes that already run XHT.

No extra RAM paints or weight growth—stealth is in the resin.

+12 % tensile modulus vs. standard aerospace epoxies.

Broadband absorption from 5 to 18 GHz with a single 2–3 mm skin.

Process window

RTM or autoclave: 100 °C × 4 h @ 2 bar (default).

Optional post‑cure 150 °C × 2 h → Tg ≈ 155 °C.

Shelf life: 12 months @ 22 °C; pot life: 120 min @ 25 °C.

Typical uses

Winglets, flaps, pylons in CFRP, stealth fuselage skins, internal shear‑webs that also need dielectric loss control.

NEMESIS™ BX‑Lite

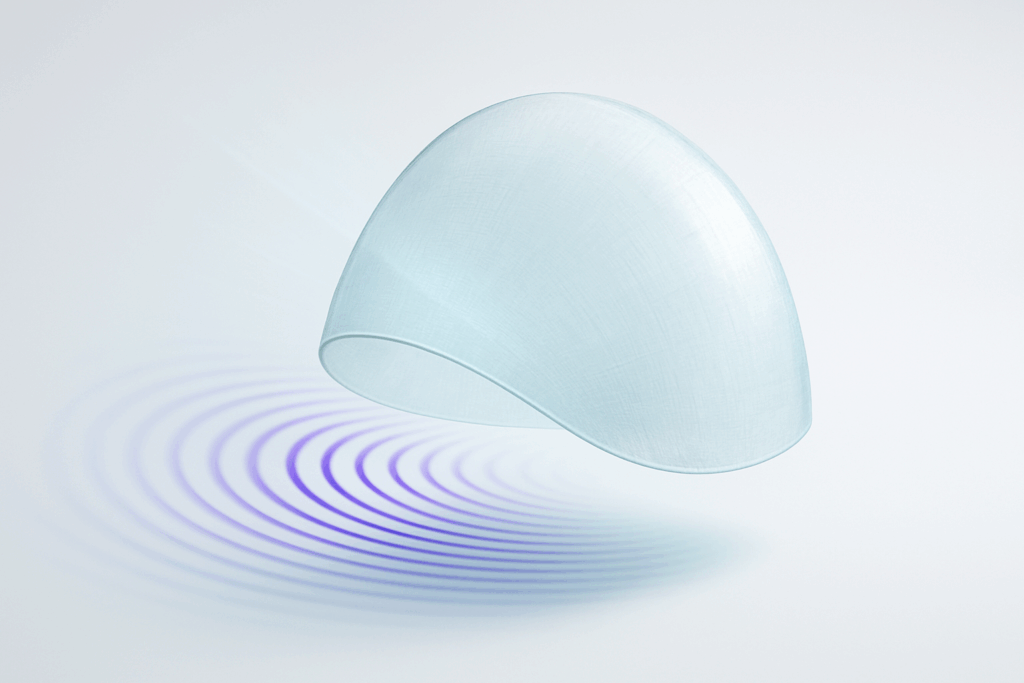

The glass‑fiber variant that turns a radome into a stealth shield

NEMESIS™ BX‑Lite — Glass‑Fiber, Radome‑Grade Stealth

Swap your standard glass‑epoxy for BX‑Lite and watch a simple radome turn into a low‑observable shield—no metallic coatings, no exotic processes, no rewrite of your BOM. The tuned dielectric mix maintains RF transparency while soaking up back‑scatter, giving designers true control over signature and RF performance in one move.

Variants at a glance

| Variant | What it is | Why you’d choose it |

|---|---|---|

| BX‑Lite | 0.5 % filler for GFRP | –11 dB broadband absorption with full radome transparency and Tg 140 °C. |

| BX‑Core | 1 % filler, higher loss | –14 dB typical; ideal for thicker fairings or bolt‑on LO panels on legacy airframes. |

| BX‑Gradient | 2 → 1 → 0.5 % stacked layers | –18 dB ultra‑wideband; cure at 6 bar to fine‑tune the notch for critical antenna bays. |

| Property (typical) | Value* |

|---|---|

| Hybrid nano‑filler content | 0.5 wt % |

| εʀ @ 6 GHz | 6.0 ± 0.2 |

| tan δ @ 6 GHz | 0.18 |

| RCS attenuation† | –11 dB @ 10 GHz, 25° |

| Tensile modulus (BX 600 g m⁻², 2 bar) | 26 GPa laminate |

| Post‑cure Tg | 140 °C |

| Viscosity 25 °C | 1 150 cPs |

* 3 mm laminate, 100 °C × 4 h cure. † Arch‑type measurement

Key benefits

Designed for GFRP radomes and fairings—εʀ and tan δ tuned for transparency + loss.

Process identical to standard glass‑epoxy; no special release films.

Cost‑effective stealth upgrade for legacy platforms.

Absorption notch can be shifted ±0.5 GHz simply by curing at 2 – 6 bar.

Process window

RTM: resin 45 °C, ΔP 0.8 bar; autoclave 100 °C × 4 h @ 2 bar.

High‑density option: 6 bar for >55 % FVF and frequency tuning.

Shelf life: 12 months @ 22 °C.

Typical uses

Helicopter and UAV radomes, bolt‑on stealth panels, sensor covers and LO fairings made in glass‑epoxy.

Synergy with XHT‑based materials

| Integration scenario | S‑Lite + XHT (carbon) | BX‑Lite + XHT (carbon) |

|---|---|---|

| Co‑curing primary structures | Outer skins in S‑Lite for stealth, cores/webs in XHT—single autoclave run, flawless interface. | Not applicable (different fiber families), but BX‑Lite parts can be co‑bonded to XHT frames using Film‑Bond. |

| Hybrid radome | Carbon collar or frame in XHT co‑cured with S‑Lite face skins to keep mechanical & RF continuity. | Entire GFRP shell in BX‑Lite bolted to XHT airframe via stealth Film‑Bond. |

| Field repair / retrofit | OOA prepreg S‑Lite patches on damaged XHT CFRP restore strength and introduce local RCS damping. | BX‑Lite patches can shield specific hotspots on an existing XHT structure. |

| Stealth bondlines | Film‑Bond (unfilled NEMESIS™) replaces metallic shims—no joint echoes. | Same Film‑Bond provides dielectric coupling between BX‑Lite panels and XHT frames. |

Why the pairing works

Identical cure peak (~110 °C) → seamless co‑cure.

Similar room‑temp viscosity → shared RTM tooling.

Same epoxy backbone → >40 MPa interlaminar shear without primers.

Matched CTEs prevent residual‑stress delamination.

With NEMESIS™ S‑Lite and BX‑Lite you can add broadband stealth to any XHT‑based component—without touching your existing process window.

Access & Confidentiality

Access to detailed formulation data, processing guides and performance reports for the NEMESIS™ platform is strictly limited to customers operating under a dedicated contractual framework.

If your programme requires broadband low‑observability and you are prepared to sign a mutual Non‑Disclosure Agreement, please reach out to us at:

stealth.solutions@reinventy.com

Our team will guide you through the NDA process and discuss the most suitable contractual route for technology transfer and industrial support.

• Reinventy Solutions is not responsible for comments, interpretations or re‑use made by third parties.

• All specifications are preliminary and may change without notice; shared links should therefore cite the original URL.

• This limited permission does not convey any licence to our trademarks, images or technical data beyond the context of the original page.

See the full Master Technology & Commercial Disclaimer .

Get Started

Contact our experts for info, insights or demo material.

Email: nemesis@reinventy‑solutions.ca

Phone: +1 (539) 476-2779

Legal Disclaimer

Accessing or using the information on this page constitutes acceptance of Reinventy Solutions’ Master Technology & Commercial Disclaimer.