AeroMag™ Motors

Lightweight Power • Boundless Potential | “Magnetic composites. Maximum performance.”

AeroMag™ Motors are a new breed of electric machines built around Reinventy Solutions’ proprietary sintered soft‑magnetic composites. By replacing stacked silicon‑steel laminations with a 3‑D printable, high‑saturation Fe‑Co‑V matrix, AeroMag technology unlocks:

- Twice the power‑to‑weight ratio of today’s best radial IPMSMs.

- Seventy‑percent lower core losses, enabling near‑silent operation and smaller cooling circuits.

- Freedom of geometry – monolithic stators and rotor back‑irons can be printed in days, not machined in weeks.

From last‑mile delivery vans to e‑VTOL propulsion, AeroMag Motors deliver hyper‑car performance in a package light enough to carry under one arm.

Why AeroMag Motors

AeroMag™ drives rewrite the classic motor equation by merging high‑saturation, 3‑D printable composites with state‑of‑the‑art winding and control. The result is a platform that delivers car‑class torque at bicycle‑class weight while slashing thermal and acoustic footprints.

Key Benefits at a Glance

| Advantage | Typical Gain vs Conventional Steel | Real‑World Impact |

|---|---|---|

| Power density | +170 % (radial) / +100 % (axial) | Same performance from half the mass → extended range, vertical take‑off feasible |

| Core losses | −70 % @ 1 kHz | Smaller cooling loops; 6 dB noise reduction in HVAC fans |

| Design freedom | Monolithic, filleted stators & axial discs | No yoke plates or glue; topology‑optimised shapes in a single print |

| Rapid iteration | 1‑week print‑sinter cycle | Four design spins per month instead of one per quarter |

| Supply‑chain light | No exotic laser‑cut stacks, minimal CNC | Local 3‑D printing bureaus can produce functional cores |

Innovative Application Examples

| Sector | Use‑Case | Why AeroMag Wins |

| Urban Logistics | 48 V direct‑drive wheel hubs for last‑mile vans (R‑80) | 3 kW/kg halves battery size, PPMT start‑torque removes gearbox |

| e‑VTOL & UAV | 8‑rotor lift system, 30 kW each (A‑260 down‑scaled) | Sub‑6 kg motors enable >12:1 thrust‑to‑weight, silent due to low core loss |

| Marine Hydrofoils | 100 kW modular pod, saltwater cooled | Axial housing in CFRP + µ‑channels → zero corrosion, 94 % @ 10 knots |

| Agri‑Robotics | 60 V swappable power‑pack for autonomous tractors | High torque at stall, no rare‑earth magnets in rotor, dust‑sealed design |

| High‑speed Compressors | 30 krpm oil‑free air end | Granular insulation cuts eddy losses, EVH core stable to 180 °C |

| Portable Power Tools | 1 kW inline spindle <0.5 kg | Printable ferrule integrates gearbox, resin dampens vibration |

AeroMag™ shifts the design frontier for every application where mass, efficiency or NVH are mission‑critical.

AeroMag™ R‑80

Torque King – Compact high‑torque drop‑in for 48‑96 V e‑powertrains

AeroMag™ R‑80 combines the flux‑steering magic of Parallel‑Path technology with ULTRACORE™ Fe‑Ni composites. The result is a gearbox‑free drive unit that delivers van‑grade torque from a package smaller than a basketball. Designed for retrofit and new‑build LCVs, mobile robotics and marine pods, R‑80 runs silently, starts in any rotor position without sensors, and shares a common 48–96 V DC bus with batteries, solar or fuel‑cell stacks.

Key features

• Instant start torque – PPMT topology produces 150 % rated torque at zero speed.

• Ultra‑quiet – 6 dB lower core “whine” than BLDC of equal power.

• Inverter friendly – works with low‑cost 100 V MOSFET bridges (no SiC needed).

• Maintenance‑free – rotor is a single piece of composite + steel, no magnets to delaminate.

• Field‑replaceable – weight <26 kg; can be installed by one technician in under 30 minutes.

| Parameter | Value | Notes |

| Rated mechanical power | 80 kW | at 2 000 rpm, sea‑level 25 °C |

| Peak mechanical power | 120 kW / 30 s | software‑limited |

| Rated torque | 380 N·m | continuous, Id optimised |

| Peak torque | 570 N·m / 10 s | locked‑rotor safe |

| Speed range | 0 – 3 800 rpm | flux‑weakening above 2 000 rpm |

| Efficiency (η🔄) | 93 % (typ.) | measured IEC‑60034‑2‑1 |

| Voltage range | 48 – 96 V DC | ripple ≤ 5 % |

| Max DC‑bus | 108 V | absolute rating |

| Inverter | 6‑FET 100 V, 300 A | TMC6200 gate + IPT015N10N5 FETs |

| Encoder / sensor | AS5047P 14‑bit, on‑axis | optional UVW output |

| Cooling | Oil jacket 4 l/min | 60 °C inlet |

| Core material | ULTRACORE™ Fe‑Ni | Bsat 1.7 T, ρ 6.8 g cm⁻³ |

| Winding | Hair‑pin Cu 4 × 2 mm | slot‑fill 83 % |

| Magnet blocks | NdFeB N52 segmented | 12 segments per pole |

| Outer diameter | 350 mm | incl. housing fins |

| Active length | 180 mm | three × 50 mm stacks + end‑caps |

| Shaft diameter | 32 mm | hollow option for coolant |

| Mass | 26 kg | without oil |

| Power density | 3.1 kW / kg | |

| Torque density | 14.6 N·m / kg | |

| Compliance | CE, RoHS, IEC 60034‑5 IP67 | E‑mark pending |

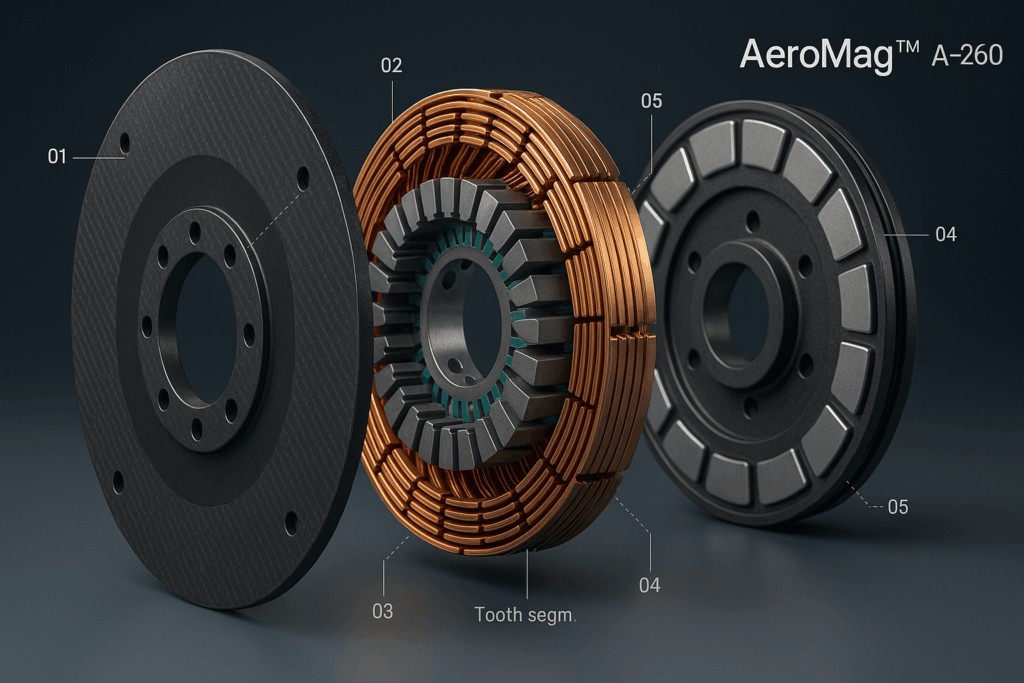

AeroMag™ A‑260

Power Feather – 260 kW of flight‑grade thrust in a 25 kg disk

AeroMag™ A‑260 leverages the EVH™ Fe‑Co‑V composite in a yokeless double‑rotor, single‑stator axial‑flux configuration. The printed core integrates micro‑channels for direct water cooling and supports hair‑pin windings with an 83 % slot‑fill, while a carbon‑fibre back‑disk slashes rotational inertia. Designed for e‑aviation, hyper‑cars and high‑speed marine foils, A‑260 delivers megawatt‑class acceleration with half the mass of legacy axial machines.

Key features

• Ultra‑high power density – 10.4 kW/kg continuous, 14 kW/kg 30 s burst.

• Silent core – EVH’s granular insulation makes eddy‑loss noise undetectable above 1 m.

• Integrated cooling – 1 mm serpentine channels cut ΔT coil‑core by 15 °C.

• Field‑serviceable rotors – magnet rings bolted to CFRP disks, swap in <20 min.

• 800 V SiC ready – matches aviation and supercar voltage stacks.

| Parameter | Value | Notes |

| Rated mechanical power | 260 kW | at 2 500 rpm, 25 °C |

| Peak mechanical power | 370 kW / 30 s | FW zone |

| Rated torque | 1 000 N·m | continuous |

| Peak torque | 1 450 N·m / 10 s | |

| Speed range | 0 – 5 000 rpm | FW above 2 500 rpm |

| Efficiency (η🔄) | 96 % (typ.) | IEC‑60034‑2‑1 |

| Voltage range | 600 – 800 V DC | |

| Max DC‑bus | 870 V | absolute rating |

| Inverter | SiC 600 A, 15 kHz | liquid cooled |

| Encoder / sensor | Resolver 17‑bit | aviation grade |

| Cooling | Water µ‑channels 8 l/min | 30 °C inlet |

| Core material | EVH™ Fe‑Co‑V | Bsat 2.1 T |

| Winding | Hair‑pin Cu 4 × 2 mm | slot‑fill 83 % |

| Magnet rings | NdFeB48SH 6 mm | Halbach option |

| Outer diameter | 420 mm | incl. housing |

| Active thickness | 40 mm core + 2× rotor | |

| Shaft / interface | Ti‑6Al‑4V hub Ø 30 mm | hollow coolant return |

| Mass | 25 kg | dry |

| Power density | 10.4 kW / kg | |

| Torque density | 40 N·m / kg | |

| Compliance | CE, RoHS, DO‑160, IP67 | e‑aviation roadmap |

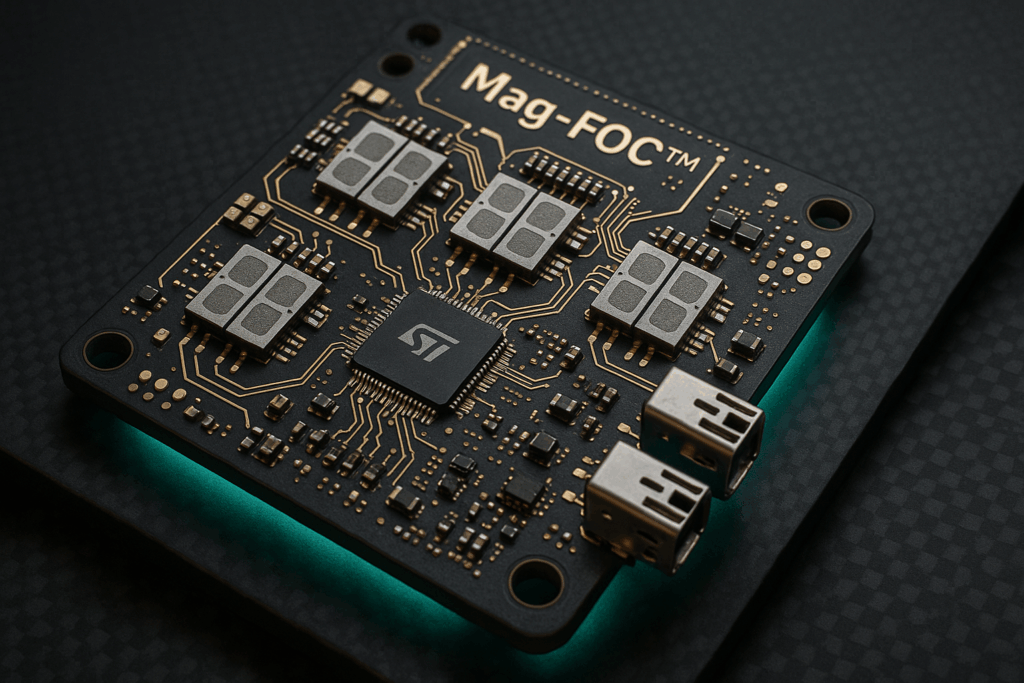

Mag-FOC™ Smart‑Drive Platform

One firmware, two footprints – scalable from 48 V vans to 800 V e‑propulsion.

What it is

Mag‑FOC™ is Reinventy’s unified flux‑oriented control stack and power‑electronics hardware.

A common MCU core, encrypted dual‑image firmware and AI‑Health diagnostics drive both the LV‑300 (low‑voltage R‑Series) and HD‑800 (high‑voltage A‑Series). Swap the power stage, keep the brains: the tool‑chain, parameter workflow and telematics are identical across the range.

Key Features — Road‑Map Highlights

- Ultra‑Fast Control Loop — 6 µs ADC‑to‑PWM latency, 10 kHz Id/Iq update, 20 kHz SVPWM.

- AI‑Powered Diagnostics — Tiny‑ML vibration & thermal model predicts Remaining‑Useful‑Life within ±8 %.

- Secure Dual‑Image OTA — AES‑256‑GCM‑encrypted updates with instant roll‑back and hardware root of trust.

- 2 µs Hard‑Shutdown — desat over‑current, over‑voltage clamp and gate‑kill line meet DO‑160 surges & ISO 26262 ASIL‑C.

- Multi‑Protocol Gateway — CAN‑FD 5 Mbit/s, EtherCAT‑CoE 100 Mbit/s, USB‑C DFU/CLI on both variants.

- Auto‑ID & Self‑Tuning — 2‑s chirp identifies Rs, Ld/q, flux‑linkage and cogging profile for any AeroMag motor.

- Modular SiC Power Stage — field‑swappable IMS half‑bridges; LV 100 V copper 200 µm, HV 1200 V copper 400 µm.

- Integrated Micro‑Channel Cooling — nickel plate keeps junctions ≤ 90 °C at 600 A with only 0.5 l/min glycol.

- Open Telemetry Stack — MQTT via EtherCAT or CAN‑FD; feeds Fleet‑Hub dashboards and cloud ML retraining.

| Variant | Key specifications | Typical pairing |

|---|---|---|

| Mag‑FOC LV‑300 R‑Series (48‑120 V) |

|

AeroMag R‑80 (80 kW) R‑60 • R‑40 |

| Mag‑FOC HD‑800 A‑Series (600‑800 V) |

|

AeroMag A‑260 (260 kW) Dual‑unit 520 kW stacks |

Common Platform DNA

-

Same MCU & Firmware — STM32G4 dual‑bank, Mag‑FOC™ runtime with 6 µs latency, EKF sensorless fallback, AI‑Health diagnostics.

-

Secure OTA & Dual‑Image — identical AES‑256‑GCM update engine; LV‑300 and HD‑800 receive firmware from the same CI pipeline.

-

Multi‑Protocol Gateway — CAN‑FD 5 Mbit/s, USB‑C CLI/DFU on both; EtherCAT‑RMII populated by default on HD‑800, optional on LV‑300.

-

Plug‑and‑Play Motor ID — power‑up chirp auto‑identifies R‑Series or A‑Series constants and loads matching parameter set.

-

Hardware‑Level Safety — 2 µs desat over‑current, 5 µs over‑voltage, functional‑safety roadmap to ISO 26262‑ASIL C (both variants).

What’s Different?

| Aspect | LV‑300 (R‑Series) | HD‑800 (A‑Series) |

|---|---|---|

| Power stage | 100 V SiC FETs, IMS copper 200 µm | 1200 V SiC FETs, IMS copper 400 µm |

| Shunt network | 0.75 mΩ inline, ±400 A | 0.5 mΩ inline, ±800 A |

| Cooling plate | 2‑port aluminium, M6 | 2‑port stainless, G¼ BSPP |

| Connectors | LV sealed AMP 8‑pole | HV shielded Amphenol SurLok Plus |

| Isolation | Functional (1500 V DC) | Reinforced (3750 V DC) |

Quick Integration Guide

- Choose the variant based on motor bus voltage.

- Use Mag‑FOC Studio → Auto‑ID — the tool automatically loads coil inductance, flux‑linkage and flux‑steering tables appropriate for R‑ or A‑Series motors.

- Mount and plumb the micro‑channel cooling plate; connect CAN‑FD and optional EtherCAT.

- Flash the latest build (same

.binfor both variants) — the bootloader detects hardware and configures desat thresholds, dead‑time and gate‑driver bias. - Run the 15‑second calibration spin; the HD‑800 engages flux‑weakening above 2 500 rpm automatically, while the LV‑300 remains in full‑flux mode.

Result: one cohesive drive ecosystem that scales from a 48 V delivery van (R‑80 + LV‑300) to an 800 V e‑VTOL rotor (A‑260 + HD‑800) without changing firmware branches or toolchains.

Extended Benchmark

How do AeroMag motors stack up?

AeroMag™ machines do not just edge out conventional designs—they leapfrog entire generations of technology. The tables below compare the continuous performance metrics and high‑level business factors of our R‑80 and A‑260 against representative commercial motors across every mainstream topology.

Performance Density Overview

| Technology | Commercial reference | Architecture | Cont. power (kW) | Mass (kg) | kW/kg | Torque dens. (N·m/kg) | Max bus V |

| Induction | Siemens IEC 160M‑15 | Radial cage | 15 | 119 | 0.13 | 0.8 | 400 AC |

| SynRM | ABB HO 37 kW | Radial | 37 | 157 | 0.24 | 1.5 | 400 AC |

| SRM | Turntide Gen‑3 12/8 | Radial reluctance | 75 | 35 | 2.14 | 5.1 | 120 DC |

| IPMSM | Tesla Model 3 DU | Radial PM | 220 | 80 | 2.75 | 3.9 | 450 DC |

| Axial‑flux PM | YASA 750R | AF dual‑rotor | 200 | 37 | 5.4 | 18.9 | 800 DC |

| Axial‑flux PM (aero) | Siemens SP260D | AF dual‑rotor | 260 | 50 | 5.2 | 20.0 | 800 DC |

| PPMT | AeroMag R‑80™ | Radial PPMT | 80 | 26 | 3.1 | 14.6 | 96 DC |

| Axial‑flux EVH | AeroMag A‑260™ | AF EVH | 260 | 25 | 10.4 | 40.0 | 800 DC |

Technical & Commercial Parameters

| Model | Max Voltage (V) | Recommended inverter | Cooling | Key manufacturing steps | Indicative cost €/kW* | Availability |

| Siemens IEC 160M | 400 AC | Soft‑starter | Air | Stacked Si‑steel, die‑cast cage | 23 | Stock |

| ABB SynRM HO | 400 AC | VFD | Air | Si‑steel + laminated rotor | 38 | Stock |

| Turntide SRM | 120 DC | SR‑Drive | Oil | Laminated stator, segmented rotor | 55 | OEM only |

| Tesla DU | 450 DC | SiC 600 A | Glycol | IPM lamination, high‑pressure die‑cast | 70 | In‑house |

| YASA 750R | 800 DC | SiC 600 A | Oil | Axial lamination stack, laser weld | 95 | MOQ 1 000 |

| Siemens SP260D | 800 DC | SiC 600 A | Oil | AF core, Ti shaft, aerospace QA | 140 | Mil‑Aero |

| AeroMag R‑80™ | 96 DC | MOS 100 V 300 A | Oil | Printed EVH core + hair‑pin kit | 45 | Kit / Built‑to‑order |

| AeroMag A‑260™ | 800 DC | SiC 600 A | Water µ‑channel | Printed EVH + CFRP rotor | 60 | Kit / Built‑to‑order |

Pricing estimate for 500‑unit annual volume, motor‑only, ex‑works Q3‑2025.

All performance figures, prices, lead times and comparative claims contained in this brochure are pre‑production estimates based on internal testing and third‑party data available in Q2 2025. They do not constitute a legally binding offer or guarantee of performance.

Trademark & brand references — Tesla, YASA, Siemens, ABB, Turntide and all other third‑party names or marks belong to their respective owners. They are used here solely for nominative comparison and do not imply endorsement or affiliation.

Confidentiality & intellectual property — The AeroMag™ materials, processes and firmware described herein are protected by pending Canadian, U.S., EU and PCT patent filings. Redistribution of this document without written consent of Reinventy Solutions is prohibited

Jurisdiction & liability — Reinventy Solutions Corp. (British Columbia, Canada) disclaims, to the maximum extent permitted by law:

• any liability for direct, indirect, incidental or consequential losses arising from the use of this document;

• any fitness‑for‑purpose warranties, express or implied;

• any damages resulting from errors or omissions.

This disclaimer is intended to be enforceable under the laws of Canada, the United States, the European Union (Directive 85/374/EEC, Unfair Commercial Practices Directive 2005/29/EC) and relevant Asian jurisdictions including but not limited to Japan and the People’s Republic of China. Where local consumer‑protection law imposes non‑waivable rights, those rights remain unaffected.

• Reinventy Solutions is not responsible for comments, interpretations or re‑use made by third parties.

• All specifications are preliminary and may change without notice; shared links should therefore cite the original URL.

• This limited permission does not convey any licence to our trademarks, images or technical data beyond the context of the original page.

See the full Master Technology & Commercial Disclaimer .

Get Started

Contact our experts for info, insights or demo material.

Email: motors@reinventy‑solutions.ca

Phone: +1 (539) 476-2779

Legal Disclaimer

Accessing or using the information on this page constitutes acceptance of Reinventy Solutions’ Master Technology & Commercial Disclaimer.