AeroMag™ - Adaptive Electromagnetic Ready‑to‑Print Advanced Magnetics

Ultra‑light 3‑D printable composites delivering high‑frequency power with 35 % less weight.

Overview

AeroMag™ is Reinventy Solutions’ breakthrough platform of soft‑magnetic composite materials engineered for additive manufacturing. By fusing nano‑engineered Fe‑Ni particles with high‑performance binders, AeroMag unlocks true 3‑D flux control, razor‑low core losses, and up to 35 % weight reduction in electric machines.

Why AeroMag™ ?

Tool‑less electromagnetics – print stators, rotors, flywheels, choke cores directly from CAD in hours.

High‑frequency ready – core‑loss as low as 10 W kg‑¹ @ 400 Hz, 1 T (EV‑H) and μr up to 150.

Lightweight efficiency – composite density down to 5 g cm‑³ (filament) vs 7.6 g cm‑³ Fe‑Si; motors up to 18 % lighter at 48 V and 10 % lighter at 400 V.

Thermal stamina – continuous service range 150 °C (EV‑L) to 200 °C (ULTRA‑CORE & EV‑H).

Circularity built‑in – printable lattices cut material mass 30 %; binder reclaim possible at end‑of‑life.

Material Variants

From rapid prototyping to full‑scale electric‑vehicle traction, AeroMag™ now offers five tuned formulations. Compare processes and magnetic performance at a glance, then pick the variant that drives your voltage and power target.

| Variant | Printing Technology | Post‑Process | μr (1 kHz, 0.3 T) | Core Loss 400 Hz / 1 T | Density | Notes |

|---|---|---|---|---|---|---|

| AeroMag‑P | FDM / FFF Filament 60 wt % Fe‑Ni in PC |

2 h @ 125 °C air cure | 90 | ≤ 40 W kg‑¹ | 5.1 g cm‑³ | Ready‑to‑use; print → cure → assemble |

| AeroMag‑UV | 405 nm DLP Photopolymer 58 wt % Fe‑Ni |

Rinse + UV + 120 °C 1 h | 100 | ≤ 30 W kg‑¹ | 5.3 g cm‑³ | Surface Ra ≤ 4 µm |

| AeroMag‑UV Ultra | Same as UV | Debind + anneal 650 °C N₂ 30 min |

140 | ≤ 20 W kg‑¹ | 6.8 g cm‑³ | High‑power motors (≥ 1 kW) |

| AeroMag‑EV‑L™ | FDM Filament 62 wt % Fe‑Si / Ni in PPS | 2 h @ 150 °C air cure | 95 | ≤ 30 W kg‑¹ | 5.1 g cm‑³ | 48 V EV motors λ 0.8 W m‑¹ K‑¹ |

| AeroMag‑EV‑H™ | DLP resin + sinter Fe‑Co 64 wt % | Debind + anneal 700 °C N₂ | 150 | ≤ 10 W kg‑¹ | 6.8 g cm‑³ | 400 V traction motors λ 5 W m‑¹ K‑¹ |

Technology in Action

Electronically Clean Interfaces – each Fe‑Ni particle carries a nano‑silicate “H‑layer” insulation, blocking eddy currents up to 5 kHz while preserving high saturation (> 1.4 T).

Smart Rheology – proprietary dispersants keep viscosity below 3 Pa·s (UV) and 300 Pa·s (filament) for flawless 50–150 µm layers.

Scalable Post‑Processing – choose a simple 125 °C air cure for rapid prototyping or an industrial debind‑anneal cycle for maximum performance.

Typical Applications

Drone & eVTOL motors – outrunners 22–40 mm, 10 000–20 000 rpm.

E‑bike mid‑drives & quadricycles – 48 V systems, 2–8 kW.

Passenger‑car traction drives – 400–800 V, 50–150 kW IPM and axial‑flux motors (EV‑H).

High‑frequency inductors – PFC chokes, flyback transformers 100–400 kHz.

Custom actuators – magnetic gears, voice‑coil shells, micro‑gimbals.

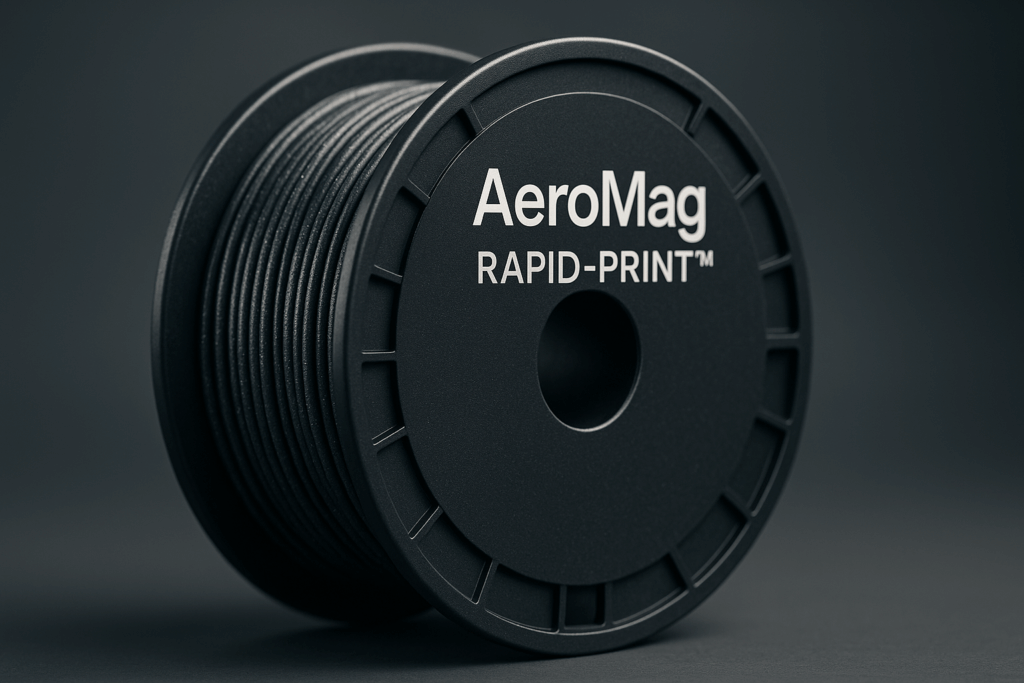

AeroMag RAPID‑PRINT™

Lightweight Ready‑Print Soft‑Magnetic Filament

Description: AeroMag RAPID‑PRINT™ (AeroMag-P) is a 60 wt % Fe‑Ni composite filament (1.75/2.85 mm) in a high‑temperature PC matrix. Print complex stators or choke cores on any enclosed FDM printer, then simply air‑cure 2 hours at 125 °C—no inert ovens, no debinding.

Technical Specifications

Continuous Service Temperature: 145 °C

Magnetic Permeability: μr ≈ 90 (1 kHz, 0.3 T)

Core Loss: ≤ 40 W kg‑¹ @ 400 Hz, 1 T

Electrical Resistivity: 12–18 k µΩ cm

Density: 5.1 g cm‑³

Filament Diameter: 1.75 ± 0.05 mm (2.85 mm option)

Key Applications

Drone & e‑bike motors ≤ 1 kW

High‑frequency inductors (100–400 kHz)

Prototyping 3‑D flux paths & custom actuators

AeroMag DURA‑CURE™

High‑Definition Photopolymer for Precision Magnetics

Description: Formulated for 405 nm DLP/LCD printers, AeroMag DURA‑CURE™ (AeroMag-UV) packs 58 wt % Fe‑Ni into a low‑viscosity resin (2.8 Pa·s). Achieve <200 µm layers, rinse & post‑cure (UV + 120 °C × 1 h) for smooth, ready‑to‑use parts with enhanced permeability.

Technical Specifications

Continuous Service Temperature: 150 °C

Magnetic Permeability: μr ≈ 100

Core Loss: ≤ 30 W kg‑¹ @ 400 Hz

Cure Depth: 200 µm @ 35 mW cm‑²

Density: 5.3 g cm‑³

Key Applications

Micro‑motors, voice‑coil cores, MEMS actuators

Power‑dense PCB inductors & planar transformers

Lattice cooling channels for compact drives

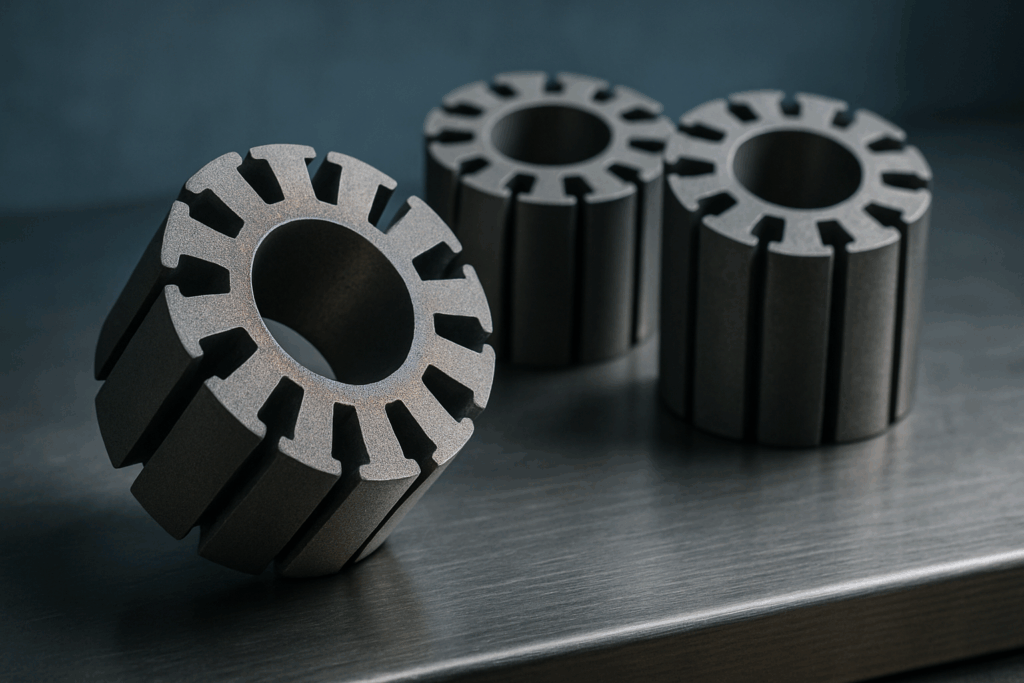

AeroMag ULTRA‑CORE™

High‑Power Sintered Soft‑Magnetic Composite

Description: Starting from the DURA‑CURE™ feedstock, AeroMag ULTRA‑CORE™ (AreoMag – UV Ultra) undergoes a debinding + 650 °C nitrogen anneal, transforming into a densified metal matrix for maximum magnetic performance and thermal conductivity.

Technical Specifications

Continuous Service Temperature: 200 °C

Magnetic Permeability: μr ≈ 140

Core Loss: ≤ 20 W kg‑¹ @ 400 Hz

Density: 6.8 g cm‑³

Thermal Conductivity: ≈ 5 W m‑¹ K‑¹

Key Applications

High‑power ≥ 1 kW e‑drives & generators

Liquid‑cooled stators & axial‑flux machines

Aerospace actuators requiring 200 °C duty

AeroMag EV‑L™

Light‑Voltage EV Filament for 48 V Drives

Description: AeroMag EV‑L™ builds on RAPID‑PRINT technology with a 62 wt % Fe‑Si / Ni blend in PPS for higher permeability (μr ≈ 95) and lower core loss at 600 Hz. Ready‑print FDM + 150 °C air cure.

Technical Specifications

Continuous Service Temperature: 150 °C

Magnetic Permeability: μr ≈ 95

Core Loss: ≤ 30 W kg‑¹ @ 600 Hz

Density: 5.1 g cm‑³

Thermal Conductivity: 0.8 W m‑¹ K‑¹

Key Applications

48 V e‑bike & quadricycle motors (2–8 kW)

Low‑voltage generators & PFC chokes

Rapid prototyping light‑EV drives

AeroMag EV‑H™

High‑Voltage Sintered Composite for 400 V Traction

Description: Designed for passenger‑car traction (50‑150 kW), EV‑H™ uses 64 wt % Fe‑Co V powder printed via DLP and fully sintered at 700 °C, achieving μr ≈ 150 and core loss ≤ 10 W kg‑¹ @ 400 Hz.

Technical Specifications

Continuous Service Temperature: 200 °C

Magnetic Permeability: μr ≈ 150

Core Loss: ≤ 10 W kg‑¹ @ 400 Hz

Density: 6.8 g cm‑³

Thermal Conductivity: 5 W m‑¹ K‑¹

Key Applications

400 V passenger‑car traction motors

Liquid‑cooled IPM & axial‑flux machines

Aerospace e‑propulsion up to 220 °C

• Reinventy Solutions is not responsible for comments, interpretations or re‑use made by third parties.

• All specifications are preliminary and may change without notice; shared links should therefore cite the original URL.

• This limited permission does not convey any licence to our trademarks, images or technical data beyond the context of the original page.

See the full Master Technology & Commercial Disclaimer .

Get Started

Contact our experts for info, insights or demo material.

Email: aeromag@reinventy‑solutions.ca

Phone: +1 778 404 0050

Legal Disclaimer

Accessing or using the information on this page constitutes acceptance of Reinventy Solutions’ Master Technology & Commercial Disclaimer.